Defect Monitoring & Inspection

LUT also gives overhaul and repair shops the ability to test manufactured components of equipment such as aircraft for structural defects and metallurgical properties while the equipment is still in service.

- Aerospace

- Auto

- Oil and gas pipeline

- Steel and cast iron

- Shipbuilding

- Semiconductor

- Electronic components and packages

- Medical devices

- Ceramics

- Glass bottling

The enhanced measurement capabilities of LUT enable manufacturers to improve quality and control the cost of parts with the added advantage of reducing the cost of stopping production lines to correct part defects.

Laser Ultrasonic Kit for Starters (LUKS-1550-TWM)

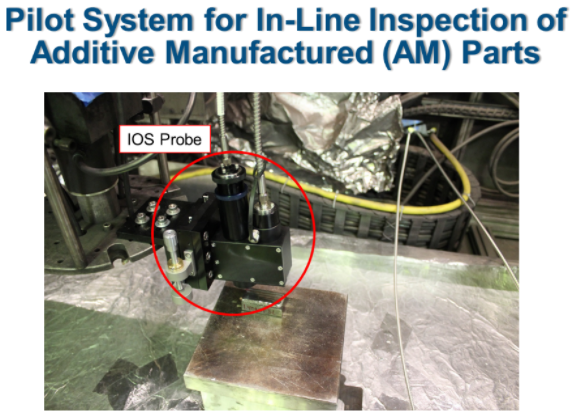

With added integration, the LUKS-1550-TWM can perform factory process monitoring and inspection, and in-service inspection in the field.

Laser Ultrasonic Receiver (AIR-1550-TWM)

The operating wavelength also enables the AIR-1550-TWM to work effectively with simple, low-cost laser sources such as DFB or fiber lasers, reducing system cost and eliminating laser maintenance concerns.

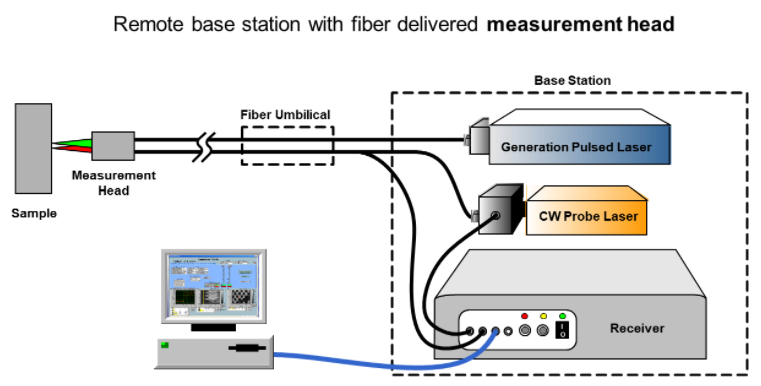

The AIR-1550-TWM includes a compact fiber-coupled measurement head. This sensor head enables remote measurement and is ideal for use with complex configurations or where measurement access is limited.